[2002-07-03] Puzzle chairs

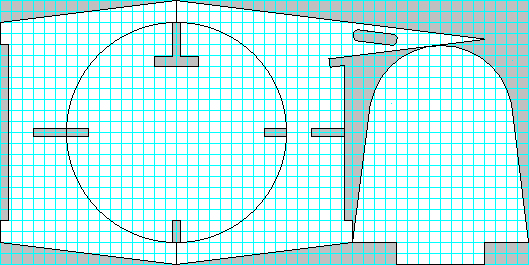

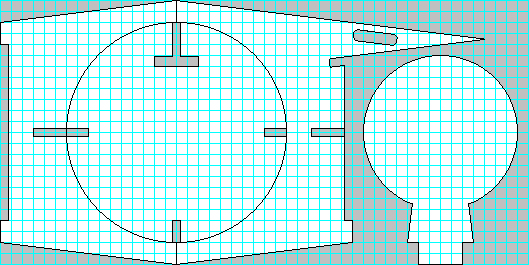

This chair was my first design project after reading Victor Papanek's Design for the Real World. My enthusiasm for Papanek's book led me, in turn, to his collaborative Nomadic Furniture and Nomadic Furniture 2, with James Hennesey. These books are filled with plans for functional, good-looking, easily built furniture designed with an eye towards simplicity and the minimization of waste. Even though the first book speaks of the pointlessness of building one's own chairs when so many are readily available second hand inexpensively, both NF1 and NF2 contain many designs for chairs, although they are, admittedly, mostly lounges or "easy" chairs. The puzzle chair is made out of four parts cut from a single piece of 2' x 4' 3/4" oak plywood, according to the plan below.

The major innovation here is in the layout of the parts on the parts-blank, specifically, that the lower edges of the legs and the circular perimeter of the seat are formed with a single cut. Angling the legs slightly outward allows for the "dead space" in between them to provide enough area to serve as a seat. 4 of these chairs can be had from a single piece of 4'x8' plywood. The pieces slot together stably without any adhesive or fasteners, making the chair easily collapsible for storage. An integrated handle-slot makes it easy to pick up the finished chair and move it around.

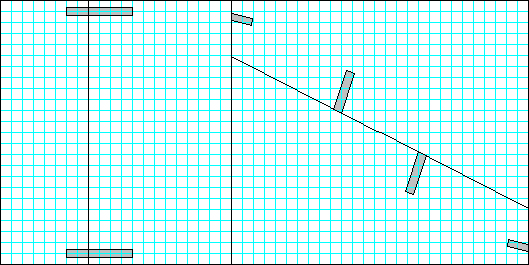

There is at least one other plan for a slot-together plywood chair that can be cut from a 2x4' blank (see below). It is, admittedly, more labor- and materials-efficient than my own design, but the chairs it produces lack both the lateral stability and the aesthetic quality of the puzzle chair. This plan I found, I think, in a book of projects published by the American Plywood Association.

The seed for the puzzle chair idea came from a cheap end-table my college roommate Phil brought with him from his parents' house. It was made from two squares and a circle of fiberboard, the squares each having been slotted halfway through so that they could interconnect stably to form an 'X' shaped base on which the circular top rested. The top had eight small MDF 'cleats' tacked to its underside which kept it from sliding around on the base. I liked the simplicity, humility, and conceptual elegance of this design, and began to wonder if I could make it any "purer" than it already was.

My first idea was to eliminate the cleats, and the tacking step they required during manufacture, by integrating some kind of alignment means into the profile of the leg- and top-pieces themselves. It occurred to me that tabs extending from the upper surfaces of the legs could interlock with slots cut into the top, preferably around the perimeter. If the length of the tabs was equal to the thickness of the material, an effectively uninterrupted, smooth table surface could be maintained. I made a plant stand using this trick, at some point, and was generally pleased with the result.

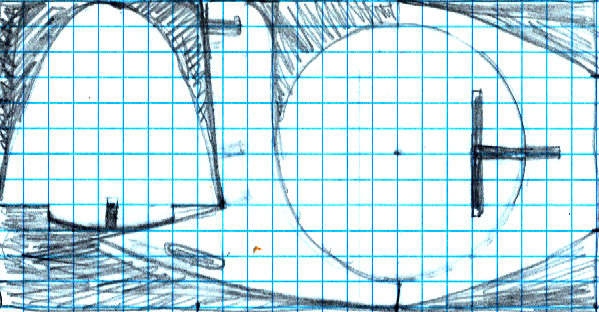

I picked up the same idea again upon reading Nomadic Furniture and deciding to design a chair, and it is evident in the first of my two prototypes (below left). The problem I had now was the relatively wasteful use of materials in the original table design; if I wanted to get four of seating height out of a standard sheet of plywood, plus additional material for the back and back-support of each chair, I had to come up with some way to cut down on the area of the leg pieces. My solution, in the first prototype, was to cut the two leg pieces not as solid rectangles, but as U-shapes, with the open end of the Us forming the four legs of the chair, and the closed ends of the Us interlocking in the traditional way. Now, the "dead space" in the middle of the U could be dedicated to other parts of the chair, and in the first prototype I used it to form the two parts which, clamped around back-supports extending from the leg-pieces, would form the back of the chair.

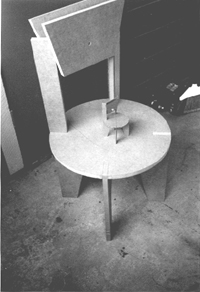

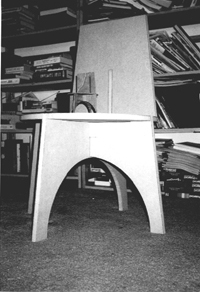

The first prototype of the puzzle chair was generally unsatisfactory. Besides requiring a single fastener to clamp the back pieces to the back supports, it was quite uncomfortable and required slightly more than the alloted 2x4' of plywood. The real breakthrough came with the second prototype. I knew I wanted the chair to have a circular seat, but the problem I had was that there was no way to cut the seat from the "dead space" between the legs and still have it be as wide in diameter as the legs. Or so I thought, until I realized I could angle the external edges of the leg pieces inward, so that they'd be wide enough at the bottom to accomodate the full diameter of the seat as "dead space," and match that diameter exactly at the top. The space savings realized by this innovation left me plenty of material in the top third of the 2x4' blank to form the seat back, and by extending a single "tab" from one of the leg pieces upward above the level of the seat, I was able to have a back-support. These were the essential steps that led me to the second prototype (below right).

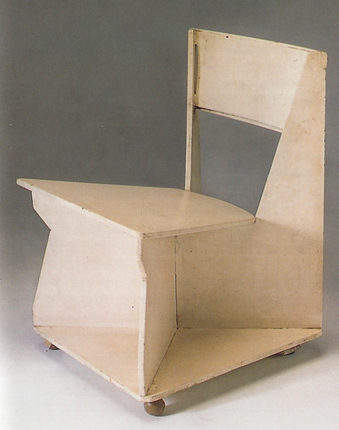

The third prototype, pictured at the top of this page, improved on the second mostly in terms of comfort and presentability: The back was angled at about 10 degrees off perpendicular with the seat, and its shape was rounded to improve the looks of the chair. A slot in the back interconnecting with the back-support tab was eliminated as unnecessary given the tendency of gravity to hold the chair together now that the back was angled. The third prototype, essentially the finished design, was cut from cabinet-grade plywood using a reciprocating saw. The edges were rounded over with a 1/4" router bit, and the leg pieces stained blue before the whole thing was varnished.

A plan for a hypothetical circle-back variant, which requires more cutting and results in more wasted material, but also (it is hoped) would leave the finished chair with a more pleasing aesthetic, is included below. Although neither this design nor the original requires any fasteners whatsoever, a single wood screw, driven through the exact center of the circle of the chair back and into the edge-grain of the support member will secure all the pieces firmly in place, so that even if the chair is inverted, it will stay together. When I have the time, I'm going to make one of these in fine birch plywood on a CNC router. The wood will be satin-varnished but otherwise unfinished; the single wood-screw will be bright hunter-orange. The idea is for the chair to be proud of its construction, not to try to conceal it.

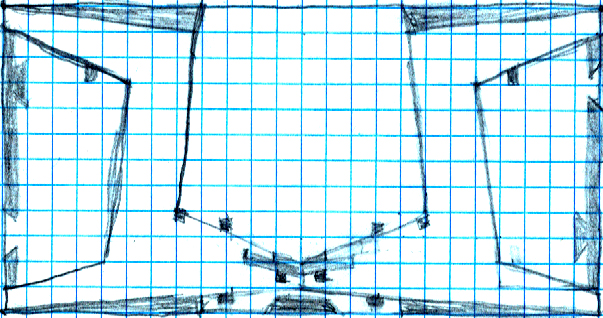

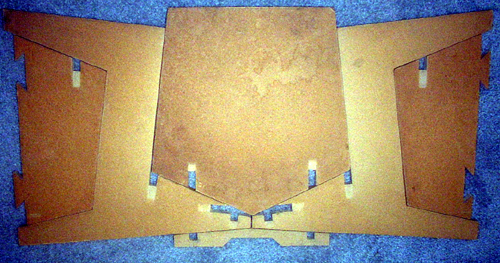

Below are presented are two rough concept sketches for other, similar interlocking designs which can be cut from a 2' x 4' plywood blank. The first does away with the cross-wise locking of the leg pieces, favoring instead a parallel bulkhead approach similar to that used by the APA chair above. Note that the chair back piece had to be cut into interlocking sections to fit the entire parts-layout in the required 2'x4' area.

And here are some photos of a prototype built from this design. It was comfortable and fit together well, but in the end proved overcomplicated.

The second concept sketch was for a three-legged variant of the puzzle chair. I'd seen some three-legged chair designs in Metropolis Magazine and decided I wanted to try one of my own. Three legged chairs tend to be more stable on uneven ground, and use less materials overall. This one was never built because the design, although feasible, involves a lot of wasted material, and I never really had the time or inclination to optimize it.

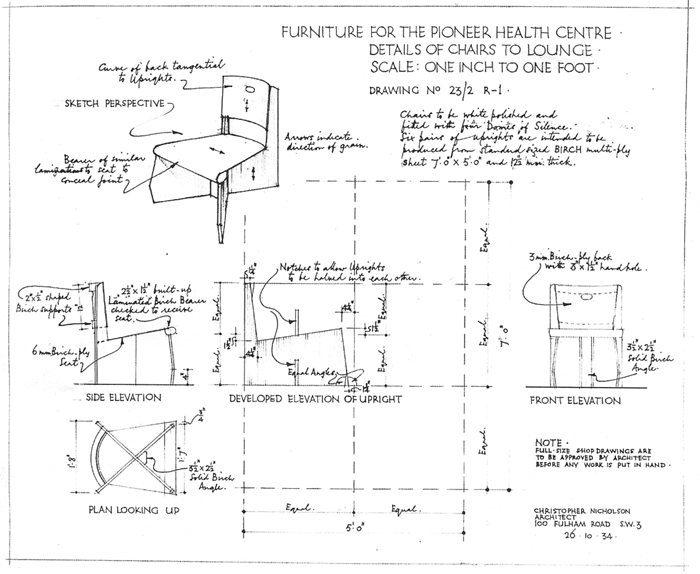

Finally, some historical precedent: The following picture is scanned from Taschen Design's fascinating book 1000 chairs. It depicts the so-called "Standard" chair created by noted British modernist architect Christopher "Kit" Nicholson for the lounge of the Pioneer Health Center in Peckham, London, in 1934. The specimen depicted below includes a wooden base-plate and castors, which may or may not be part of the original construction. Nicholson's original plan is reproduced at the bottom of the page.

The similarities between this chair and some of my own designs are obvious: First, the use of plywood; second and more particularly, the use of slotted profiles which "half into each other" (Nicholson's phrase); third and finally, the goal of minimizing wastage in the parts blank. There are also important differences. To begin with, not all of the pieces of Nicholson's chair were made from the waste-minimized blank, just the two interlocking supports. The back and seat are made of materials from other sources. Also, fasteners (glue, screws, or whatever) are used in Nicholson's design, but not in mine. Finally, it should be noted that a standard size sheet of plywood in Nicholson's world was 5x7', whereas in mine it is 4x8'.

last modified 2004-05-28